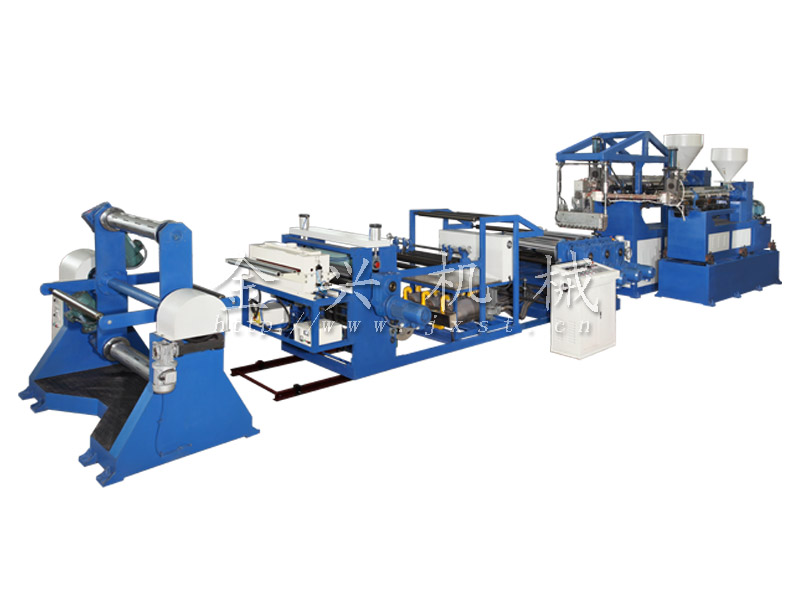

DCP Series Multi-layer Plastic Sheet Extruder

| Parameter | DCP105/75-800 | DCP110/75-1000 | DCP120/75-1300 |

| Available material | PP、HIPS、GPPS、PE | PP、HIPS、GPPS、PE | PP、HIPS、GPPS、PE |

| Diameter of screw(mm) | 105/75 | 110/75 | 120/75 |

| Ratio of length and diameter of screw | 1:33 | 1:33 | 1:33 |

| width of flake board (mm) | 720 | 920 | 1220 |

| thickness of flake board(mm) | 0.1-2.0 | 0.1-2.0 | 0.1-2.0 |

| highest capacity(kg/h) | 280 | 350 | 420 |

| Power of the whole machine (kw) | 160 | 190 | 220 |

| Dimension(mm) | 15000x2200x2500 | 15000x2400x2500 | 18000x2600x2500 |

Application Field: Food packing, electronic products, blow molding and forming

Function :

1. Available for producing multi-layer plastic sheet of PP, HIPS, GPPS, EVOH and QB515.

2. The screw of extruder adopts big ratio of length and diameter.

3. Nice formed effect.

4. Equal thickness of sheet.

5. Same running speed.

6. Use advanced hydraulic pressure high speed net changing fitting without stopping the machine.

7. Convenient operation and excellent function improve the production efficiency.

8. High precision distributor, T-style mold head to ensure equal pressure and running speed out of the mold.

9. Use worm wheel to adjust pressing roller, convenient operation and high precision.

10. Brighter pressing roller surface than mirror, equal temperature of roller surface make clean, bright and homogeneous sheet.

11. Select different plastic materials to produce the compound sheet with different colors according to different products.

English

English 简体中文

简体中文